A 300 year-old traditional cotton bleaching method is combined with the ideal dyeing technique to produce colorful Yukatas.

Ishizu-gawa River, Sakai's Bleaching Method and Yukata

A cotton bleaching method using the plentiful waters of the Ishizu-gawa River started in Sakai's Kena district in the early Edo Period (about 350 years ago).

Kena's ideal location, in between the cotton textile production center in Senshu and the wholesalers in Osaka, plus its abundance of clear water and space for drying fabric in the sun helped the cotton bleaching business flourish in Sakai.

The hand-dyed yukata (casual summer kimono) business started in Sakai during World War II when this industry fled from war-damaged Osaka to the home of bleached cotton, Sakai.

This technique of hand-dyeing yukatas, called chusen, which means pouring dye, originated in the early Edo Period.

Chusen is a kind of dye blocking method using glue. First, a hand-carved pattern, called the Ise-pattern, made of Japanese washi (handmade paper) hardened with persimmon tannin is placed on the bleached fabric. Glue is applied over each pattern and fabric is carefully folded in layers. Individual dyes are poured over each pattern, leaving the glued-off areas white. This technique dyes both sides at once, and the resulting pattern hardly fades even after a long period of use.

Cotton Bleaching Process

-

Treatment vats

Removing glue, scouring, bleaching, treatment and rinsing are all done efficiently in these large vats.

Removing glue, scouring, bleaching, treatment and rinsing are all done efficiently in these large vats.

-

Rinsing

Chemicals and stains on the textile are washed off with water. -

Drying

The textile is placed into a centrifugal dryer to remove all moisture. -

Finish/Final preparation

After the textile is heat dried, it is prepared for shipment in 100 piece bundles. The bleached cotton is softened, impurities are removed, and it is given a luster.

After the textile is heat dried, it is prepared for shipment in 100 piece bundles. The bleached cotton is softened, impurities are removed, and it is given a luster.

Yukata Hand-dyeing Process (Chusen)

-

Rolling the fabric

2 to 3 rolls of bleached cotton are carefully rerolled to remove the smallest wrinkle and prepared for the next stage. -

Glue application

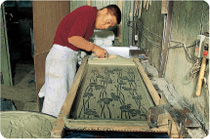

A specially formulated glue is applied evenly and thinly over a special design pattern with a large spatula. Next, the textile is folded over at the border of glued and non-glued section, then the process is repeated.

A specially formulated glue is applied evenly and thinly over a special design pattern with a large spatula. Next, the textile is folded over at the border of glued and non-glued section, then the process is repeated.

-

Building embankments

In order to dye different designs with different colors, embankments made of the same formulated glue are created around each pattern over the 3 to 4 rolls worth of glued and layered textiles.

In order to dye different designs with different colors, embankments made of the same formulated glue are created around each pattern over the 3 to 4 rolls worth of glued and layered textiles.

-

Chusen(Dye application)

A good amount of dye is applied over each pattern. A vacuum pump is used at the same time underneath to ensure even dyeing. The glued off areas remain white while the others are dyed evenly.

A good amount of dye is applied over each pattern. A vacuum pump is used at the same time underneath to ensure even dyeing. The glued off areas remain white while the others are dyed evenly.

-

Rinsing

Excess dye and glue are washed off in this washer.

Excess dye and glue are washed off in this washer.

-

Drying

After drying in a centrifugal dryer, the textile is heat dried and sent to a processing factory.

There, the textile is starched, dried, and rolled up.

After drying in a centrifugal dryer, the textile is heat dried and sent to a processing factory.

There, the textile is starched, dried, and rolled up.

[Manufacturers' Associations]

●Sakai Hand-dyeing and Bleaching Association

Kena Kaikan,

324 Kena-cho, Naka-ku, Sakai 599-8266

Phone: (072) 273-2147

URL:http://www.osaka-orisen.com/